Quality Policy

Savoy Piping Inc. is committed to its promise of 'transforming tomorrow' and the three values that underpin it -Knowledge, Innovation and Quality. These values shape our behavior. We recognize that the Company has a duty to operate in a responsible and transparent manner and to safeguard the wellbeing of all its clients, including employees, contractors and the communities in which it operates.

That's why we have a strong focus on Corporate Responsibility.

We believe its value is not only in the details of the product being supplied, but also in the Quality Process as well. This process insures consistent and meaningful communication, before, during and at the conclusion of every project we are involved with.

We believe its value is not only in the details of the product being supplied, but also in the Quality Process as well. This process insures consistent and meaningful communication, before, during and at the conclusion of every project we are involved with.

All our material is available with full Traceability records by way of Mill Certificates/Test certificates of test carried out at reputed & Govt. approved Laboratories.

We can provide for the third party inspection of our products from reputed agencies such as LLOYDS, EIL, H&G, TCE, PDIL, MECONS, M.N. DASTUR & Co., Bax council, DNV, Bureau Veritas, DPG, etc.

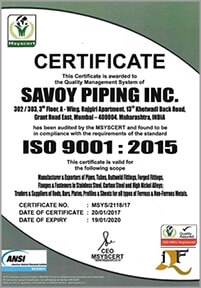

Certification

and Approval

Qualtiy Control

and Testing

Savoy Piping Inc., has always inculcated and followed stern quality standards for all of its manufacturing processes. All the materials used by Savoy Piping Inc., are of premium quality and compatible with latest machineries and manufacturing technologies. The technical and commercial quality guidelines of Savoy Piping Inc., are set to high standards.

A quality control team supervises quality assurance and control aspects along with the entire process system by recognizing and associating with the quality circle. The quality control tests are conducted regularly in order to maintain a consistent and uniform product quality.

Two kinds of testing processes, destructive and non-destructive testing, are undertaken at Savoy Piping Inc.,:

| Destructive Testing | Non-Destructive Testing |

|

|